ABOUT US

FIRST-CLASS PRODUCTS AND SERVICES IN PRECIOUS METALS

Since Dr. Theodor Wieland founded the company in 1871 its name WIELAND Edelmetalle stands for tradition and innovation, quality products and customer orientation. With more than 150 employees, technical expertise and the flexibility of a medium sized organization, today we are a high-performance company with products and services in the fields of recycling and precious metal technology. Embedded in the internationally successful SAXONIA Group, since 2010 we have been an essential part of a leading European supplier of precious metal recycling and processing. The focus of our company are high-quality precious metal and special alloys, among others for the dental and medical technology, precious metal semi-finished products for technical and decorative applications, brazing alloys and electroplating baths, as well as precious metal preparations for electroplating and the chemical industry. In addition to the production of precious metal-containing products, the recycling of precious metal-containing residues has also been a core competence of WIELAND Edelmetalle since the company was founded.

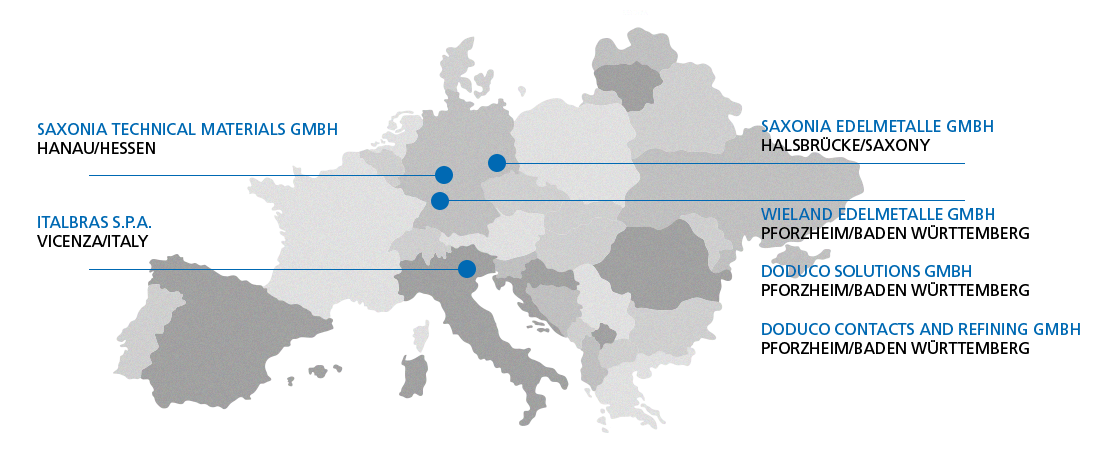

THE SAXONIA GROUP

IS ONE OF THE LEADING EUROPEAN PROVIDERS FOR PRECIOUS METAL RECYCLING AND PROCESSING.

The SAXONIA Group, with approximately 1,400 employees, consists of five high-performance companies, which together form one of the leading partners in the field of precious metal products and precious metal recycling.

SAXONIA Edelmetalle GmbH (Halsbruecke) continues the tradition of extraction and processing of precious metals that has existed in the Freiberg region since the beginning of the 17th century. Today, the company is an established and trusted partner for industrial users in the core areas of precious metal refining, precious metal chemicals, semi-finished products, platinum equipment and contact parts.

Since 2010, WIELAND Edelmetalle GmbH, Pforzheim, has been part of the SAXONIA Group. Today, WIELAND Edelmetalle is a leading medium-sized company with more than 150 employees, specializing in products and services related to precious metals refinement and technology, including semi-finished products and brazing alloys.

SAXONIA Technical Materials GmbH, Hanau and Italbras S.p.A., Vicenza / Italy, have been part of the SAXONIA Group since 2017. SAXONIA Technical Materials is your powerful partner when it comes to designing and manufacturing high-performance functional materials, custom products and innovative services based predominantly on the properties of silver, special non-ferrous metals and their alloys. With proven expertise, SAXONIA Technical Materials, the world leader in soldering and electrical contact materials, is a sought-after global partner for technically advanced and innovative solutions that create significant value for our customers.

Italbras S.p.A. is one of the leading Italian producers of brazing alloys and fluxes, marketed under the BrazeTec brand. In addition, products for electroplating and high-performance materials for the Contact & Power Technology are marketed, which are used in many industrial sectors. Engineering and consulting as well as sustainable innovations are an important success factor of Italbras S.p.A.

DODUCO, Pforzheim has also been part of the SAXONIA Group since 2020. The services of DODUCO range from precious metal recycling via stamping technology to plastic-molded assemblies. True to the motto, “One face to the customer”, we reduce supplier interfaces and create high-quality and commercially optimal solutions for our customers. Where metal and electricity come together, we offer our customers unique expertise regarding materials, surfaces and their further processing. This is how reliable contact solutions from the DODUCO company have been created for more than 100 years. Our comprehensive network of sales partners across continents enables us to have a permanent presence even in destinations without own production sites.

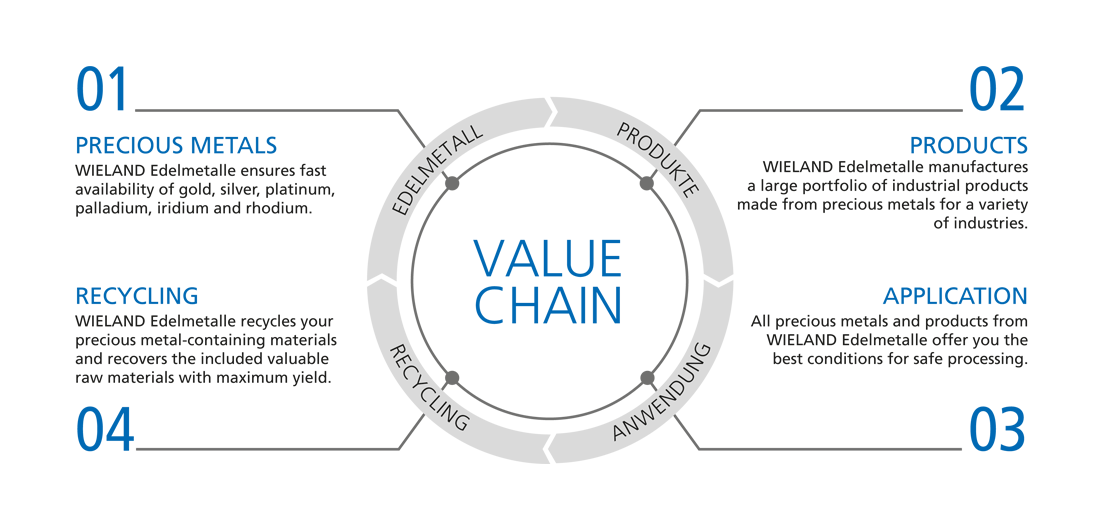

VALUE CHAIN

SUSTAINABLE. ECOLOGICAL. COMPETENT.

Precious metals are part of our daily lives: not only in the form of jewelry or as an investment, but also in smartphones, in multimedia devices, in traffic or just when the light is switched on at home. Precious metals are processed in various industries or used for the manufacture of other products – and have long become irreplaceable in modern industrial manufacturing. Today, more precious metal is needed than the earth can provide permanently. Recovering precious metal from waste in order to be able to use it again or in order to conserve resources and protect the environment is often more useful than mining. WIELAND Edelmetalle GmbH represents the complete cycle from the recycling of precious metals and their reprocessing and further processing.

RESPONSIBILITY

RESPECT. TRUST. QUALITY.

The basis of our many years of history and the continuing success of WIELAND Edelmetalle are binding corporate values that characterize our daily thinking and actions: in dealing with customers and suppliers as well as in the cooperation of our teams and employees. We value a trusting and cooperative partnership – characterized by respect, integrity and transparency. We treat our business partners with appreciation and strive to realize the optimum solution for individual customer needs: with experience, skill and vision. In addition, we follow the principle of sustainable economic success, combined with a consciously ecological handling of raw materials. This self-image is the basis for the trust of our customers in Germany and abroad.

CODE OF CONDUCT. COMPLIANCE.

As a producer and processor of precious metals, we are aware of our special responsibility along the entire value chain. Therefore, our self-understanding in the daily work includes the unconditional respect of the recognized principles of business ethics such as the respect of human rights, the respect for cultures, customs of our employees and business partners as well as strict compliance with existing laws. As a subsidiary of the SAXONIA Group, we standardize the principles of our business conduct in a Code of Conduct that applies throughout the Group.

SUPPLY CHAIN DUE DILIGENCE POLICY

As a leading company in precious metal technology, we are aware of our social, ecological and economic responsibility and are therefore committed to a social, environmentally sound and sustainable use of limited natural resources. In particular, we want to ensure that our products do not contain raw materials from illegal or unethical sources.

As a recycler of gold, silver, platinum, palladium and rhodium from precious metals bearing finished products or from used products as well as scrap, metallic and other wastes arising from the refining and production of precious metal bearing products, we do not process any mined material. We are also a manufacturer of semi-finished precious metal bearing products for various applications. At our production site in Pforzheim, Germany, we employ about 145 people.

We are a member of the Responsible Jewellery Council (RJC). The RJC is an organization that sets standards to drive responsible ethical, human rights, social and environmental practices throughout the supply chain for gold, silver, platinum group metals, diamond and color gemstone jewelry. The RJC has developed a benchmark standard for the jewellery supply chain and credible mechanisms for auditing responsible business practices through third-party auditing. As an RJC member, we commit to conduct our business in accordance with the RJC Code of Practices and the RJC Chain of Custody. We commit to integrating ethical, human rights, social and environmental concerns into our day-to-day operations, business planning activities and decision-making processes.

We conduct reviews at least once a year to assess the continued suitability and appropriateness of these business practices for achieving the policy and implement improvements to fill any gaps. For an objective confirmation of our efforts, we are regularly audited by independent third parties in accordance with the requirements of the RJC Code of Practices and the RJC Chain of Custody.In addition, we participate in the Responsible Minerals Initiative’s (RMI) Responsible Minerals Assurance Process (RMAP), which provides companies and their suppliers with an independent third-party audit to determine which smelters and refineries have demonstrated systems of responsible sourcing of minerals in accordance with current global standards.

Founded in 2008 by members of the Responsible Business Alliance and the Global e-Sustainability Initiative, the Responsible Minerals Initiative has grown into one of the most utilized and respected resources for companies from a range of industries addressing responsible mineral sourcing issues in their supply chains.

More than 400 companies and associations from over 10 industries participate in the RMI today, and we regularly collaborate with other complementary programs and initiatives in this area.

As more companies work on this issue, we hope for a future in which businesses can make greater contributions to the fostering of peace and stability in conflict-affected and high-risk areas globally.

QUALITY, ENVIRONMENT, SECURITY

QUALITY

In order to meet our own quality standards and to ensure the necessary purity and dimensional stability of our materials, we use various modern testing methods in production and quality control. In addition to the usual analysis for metallic cations (ICP-OES, AAS), our chemical laboratory can also measure the concentration of various non-metals (C/S) and the gas loading of the materials with oxygen (O2) and nitrogen (N2). In our materials laboratory, in addition to the geometry, we measure the mechanical characteristics by tensile and compressive tests, the surface roughness, the hardness (HV) and the grain size and microstructure of the materials. With the help of a continuous improvement process (CIP), we constantly increase the performance of our employees and the technical processes we use to meet our economic and environmental responsibility to our customers and our environment at all times.

The following certified management systems document the international performance and competitiveness of our company in this area:

Certifications: (download of documents)

ENVIRONMENT

Precious metals are part of our daily live: not only in the form of jewelry or as an investment, but also in smartphones, in multimedia devices, in traffic or just when the light is switched on at home. Precious metals are processed in various industries or used for the manufacture of other products – and have long become irreplaceable in modern industrial manufacturing. Today, more precious metal is needed than the earth can provide permanently. In order to recover precious metal from waste, to be able to use it again in order to conserve resources and protect the environment, recycling is often more useful than mining. As one of Germany’s leading precious metal refineries WIELAND represents the complete cycle of recycling precious metals and their further processing. We work partly with self-developed and patented processes, always with the aim of ensuring the safety and performance of our products, processes and services but always offering these services in harmony with our environment and thus reducing environmental pollution. The minimization of environmental risks is supported by the expertise of our staff and preventative technical measures to protect the soil, air and water.

SECURITY

The economic efficiency of our company is inseparable from the protection of our employees, but also the protection of our environment and the safety of our products. The consistent implementation of all relevant environmental and safety regulations is therefore our duty and enjoys our highest priority.

WHISTLEBLOWING